|

MATERIALS MILLABLE: Materials which tend to gum-up and present problems in other dry mills can often be ground in the Cyclone Sample Mill because of its patented grinding action and the low residence time in the grinding chamber. A general guideline is that materials may contain up to 20% oil or 15% moisture. Some materials containing higher levels of moisture or oil can be ground. Marginal cases are substantially aided by use of a vacuum cleaner to increase air flow. This does not result in loss of sample. |

Since many properties influence grinding characteristics, UDY Corporation personnel should be consulted regarding experience with specific materials. The applications laboratory will be happy to grind test samples and provide recommendations. If samples are corrosive or trace contamination is a concern, UDY personnel should be consulted. |

|

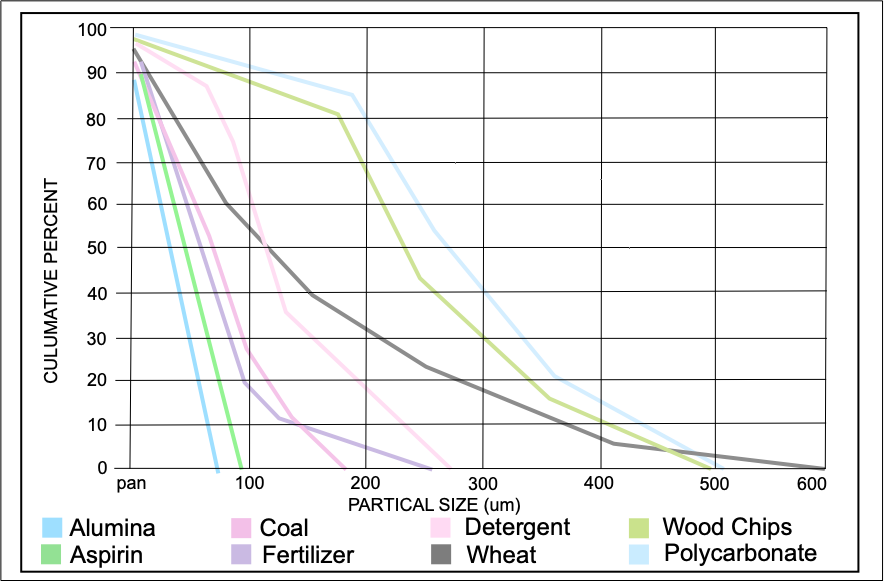

PARTICLE SIZE GENERATED: Because of the unique grinding method of the Cyclone Sample Mill, the particles exiting the mill are very small and are relatively consistent in size. This makes the Mill especially valuable for sample preparation prior to NIR measurement or other applications dependent on particle size. |

INITIAL PARTICLE SIZE: The maximum initial particle size depends on the mass and grinding properties of the material. The standard Mill Cover (shown below) limits the maximum initial particle dimension to 5 mm (1/4 inch). Low mass materials such as forages, leaves, and wood chips can be introduced in larger initial sizes by using the optional Forage Cover, illustrated in Figure 4. The Forage Cover permits feeding forage core samples directly into the Mill without preliminary grinding. |

Forage Cover for Cyclone Sample Mill

UDY Part Number: 30-0367 |

The standard Grain Cover comes with the 3010-030 Cyclone Sample Mill |

|

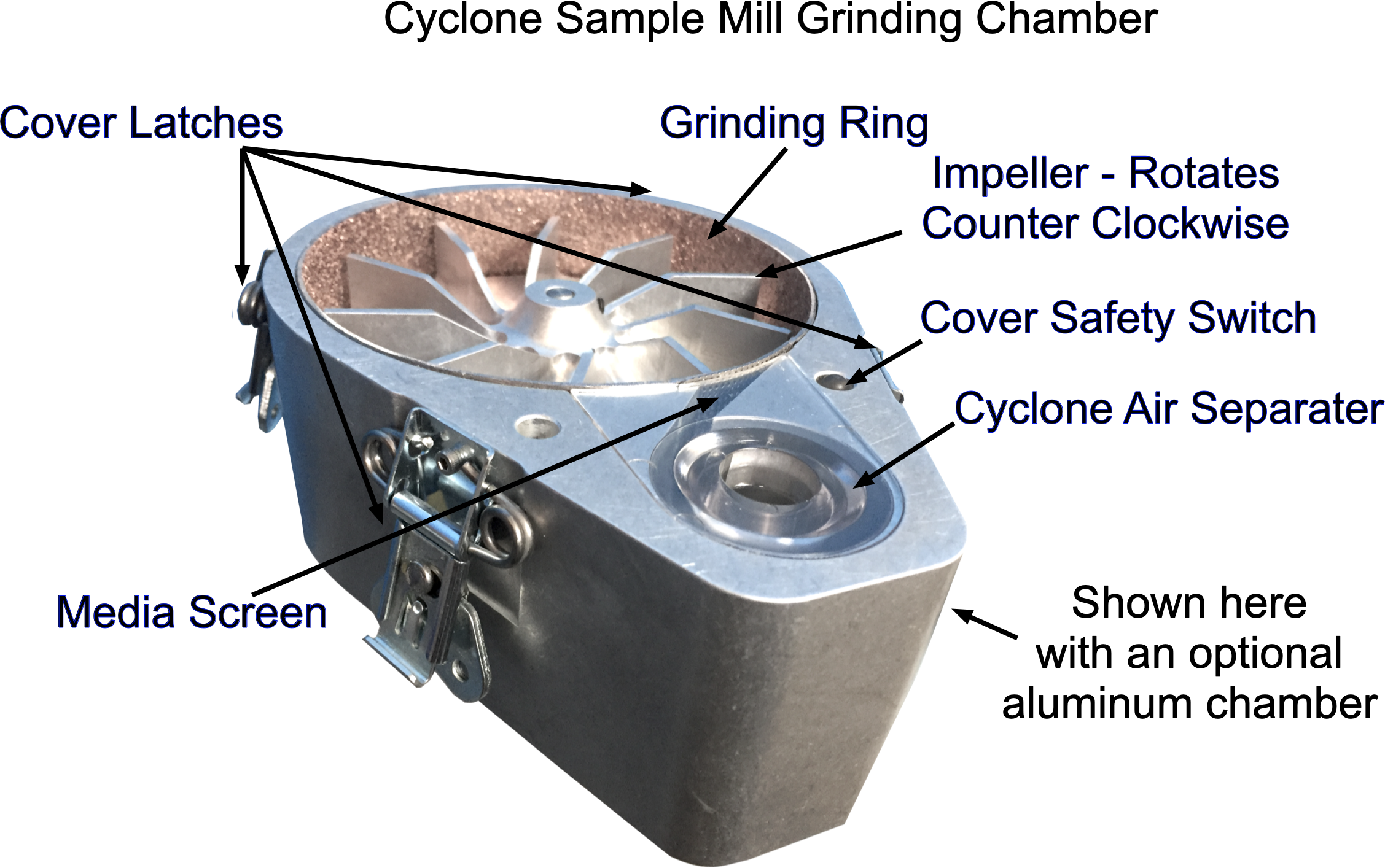

UDY Cyclone Sample Mills use a patented method of grinding. High speed rotation of the impeller and air currents throw particles into, and rolls them around the grinding ring. Particles remain in the grinding chamber until impact-shattering and abrasion make them small enough to flow out the exit with the air current. The air flow removes essentially all material and makes clean out unnecessary. The air flow also minimizes heating and therefore eliminates thermal degradation. |

|

GRINDING RATE AND COLLECTION CAPACITY: |